Aerospace Manufacturing

Specialist Aerospace Fabrication & Machining

WEC Group has been heavily involved with the Aerospace industry for over 45 years and we have fabricated complex jigs, fixtures, invar mould tools, and ground support platforms for various Tier 1 and Tier 2 companies including AeroEngine manufacturers and several Airbus assembly lines across Europe.

WEC Group is also accredited to JISQ 9100:2016) for CNC machining and Assembly (including inserts, bushes, and bearings, which has enabled us to expand further in the aviation, space and defence industries. We now manufacture a range of turned/milled and assembled flying parts for a number of international Tier 1 OEMs including precision machined components for aerostructures, landing gear, and aero tooling for composite manufacturers

Continuous investments in the latest state-of-the-art laser cutting, waterjet cutting and CNC machining technology means we can offer a fully comprehensive engineering service to the UK's highest quality, from prototype to production.

Our extensive capacity includes over 150 skilled welders, 23 flat-bed lasers capable of cutting up to 20m x 3.2m x 25mm thick, 3 tube lasers, 35+ CNC machining centres, 11 robotic welding cells, and 3 waterjet cutting machines with an accuracy that matches machined tolerances of +/- 0.1mm.

We understand the need for precision, quality and working to tight deadlines when manufacturing components for aerospace. With a large machinery line-up and a highly-skilled team of engineers, we have the capability to deliver your projects on-time and to the standards required by the industry.

We work with some of the largest aerospace companies in Europe, North America, and across the globe, and our manufacturing versatility make WEC Group an obvious choice for all Aerospace manufacturing needs.

Some of our recent Aerospace contracts are listed below.

Case Studies

Project: Ground Support Platforms and Wing Trolley

Location: Airbus Hamburg

Our specialist Aerospace division manufactured and supplied 42 different ground support platforms to be used during the various build stages of Airbus A320 Aircrafts in Hamburg.

This multi-million-pound project was manufactured in the UK over 18 months and then installed in Germany by our specialist steel erection team.

The platforms were manufactured in Mild Steel and painted white. These were then delivered and installed in Hamburg by our expert team.

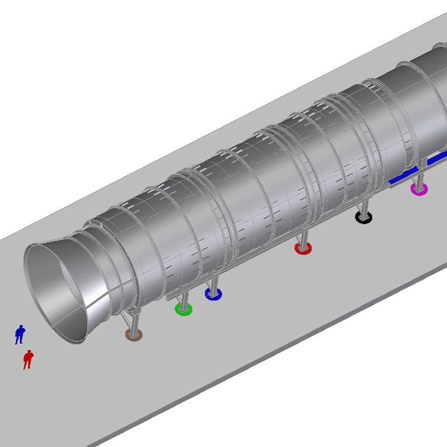

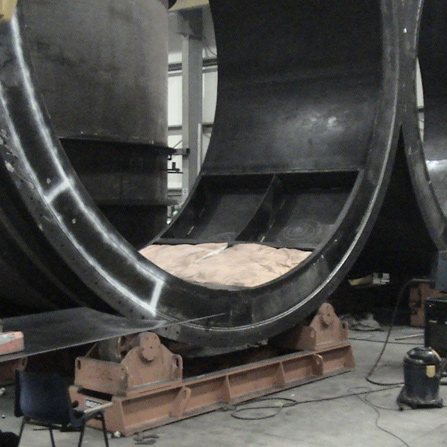

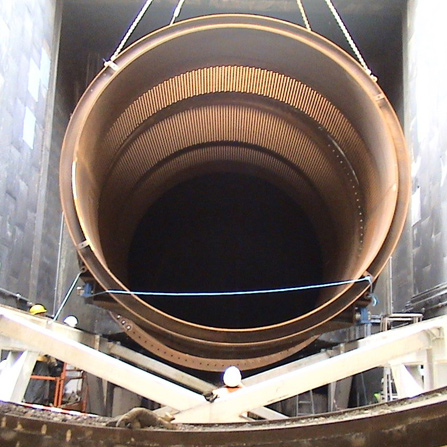

Project: Blast Baskets for Aero Engine Test Beds

Location: Various

WEC Group has fabricated and installed multiple Test Beds for various organisations such as Rolls Royce (Test Bed 54 and 80), General Electrics based in Wales and BAE Systems in Scotland.

One of our most recent projects is a 17m long x 6.5m diameter blast basket for the worlds largest indoor engine test bed facility at Rolls Royce, Derby.

The testbed will support engines such as Trent XWB and Trent 100 and will also be able to facilitate the UltraFan, which is Rolls Royce’s engine for the next generation of aircraft.

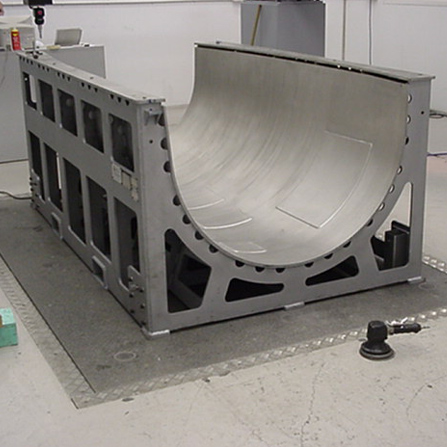

Project: Invar Mould Tools

WEC Group have been manufacturing Aerospace Mould Tools in Invar, Aluminium and Mild Steel for over 25 years.

Recent Projects include the very intricate fabrication of a Belly Panel Mould Tool out of Invar Material. The egg box was fabricated out of 1/4” thick Invar material and the Mould Tool top plate was formed out of 25mm thick Invar plate and was CMM checked prior to Welding.

It was then fabricated onto the egg box by one of our coded welders (TIG rooted and then MIG filled). The “A surface” was then precision machined down to 12mm thick and the Mould Tool was Helium Vacuum Tested prior to delivery to our customer. The project was delivered on time and on budget with quality right first time.

Project: Wing Jigs

Location: Airbus Chester

Aircrafts: A320 & A380

WEC Group has fabricated and installed Wing Jigs at various Airbus Assembly Lines in the UK.

These have included the A320 LVER Wing Jig 2 and the Jig for the A380 Metal Treatment Plant.