Robotic Welding

Robotic Welding Technology

With 12 Robotic welding cells within the Group, WEC has a wide range of modern fabrication and assembly equipment available in-house alongside a team of over 150 highly skilled welders/fabricators.

Over the past few years we have made substantial investments in the latest robotic welding technology as a way of improving our manufacturing speed, accuracy, and repeatability as well as minimising costs for our global customer base.

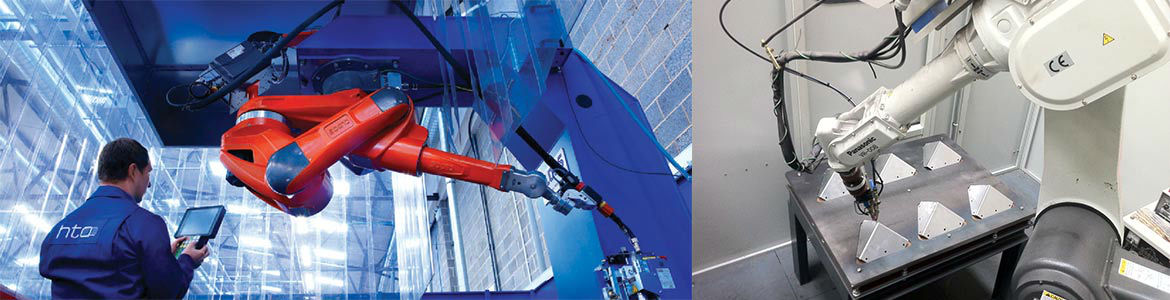

We also have a Large Format Gantry Robot Welding Cell which enables us to weld structures up to 8m long as well as an Automated Hull / Turret Welding System with a 6 axis robotic arm capable of 90 degree down weld)

Our line-up also includes modular Demmler jigging tables to allow us to create complex jigs at minimal costs with short lead times.

Benefits of Robotic Welding:

Consistent Quality & RepeatabilityRobotic welding cells have the capability to perform repeated operations for long periods of time whilst still providing a consistent level of quality. Especially for safety-critical parts, automation gives customers confidence that the quality of welds will be of the highest standard every time.

Reduced Waste

Consistent quality means there are little to no scrap/waste due to incorrect welds, something that is especially important when working on a high value job that needs to be turned around quickly.

Increased Product Manufacturing Flexibility

Robotic welding cells can weld 3 - 5 times faster than manual welders and they add flexibility to a production line. Once programmed, it can easily switch between processes meaning we are able to meet changes in product design or customer demand efficiently.