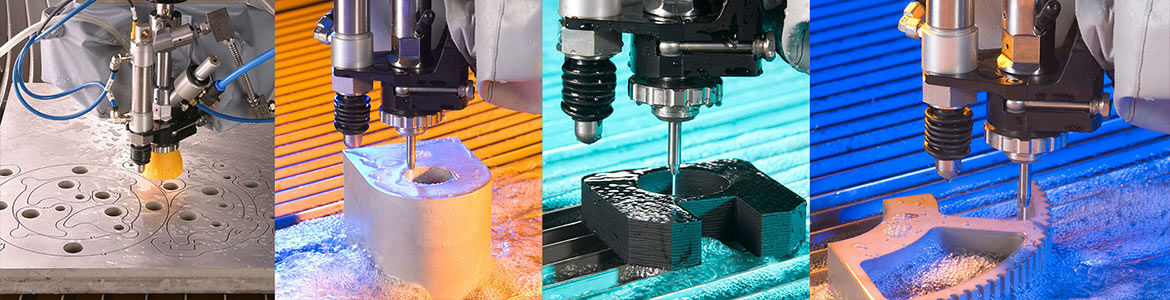

Waterjet Cutting

Dynamic Waterjet Cutting Services

Our WECJet division, also known as WEC Waterjet, provides dynamic waterjet cutting of almost any material up to 300mm thick.

Founded in 2013 and based at a state-of-the-art 17,000 sq. ft. facility in Blackburn, Lancashire, WEC Waterjet complements the Group's existing profiling services whilst offering a wider range of cutting options and materials available to customers.

The use of specialist 3D & computerised motion control sofware enables us to produce highly complex shapes as well as the capacity to waterjet cut materials up to 300mm thickness, with a bed size of 7.3 x 2.4m and an accuracy that matches machined tolerances of +/- 0.1mm.

We have also recently commissioned in a new 4m x 3m Mach 500 waterjet cutting machine, that can cut any material up to 300mm thick and 3m wide.

With 3 state-of-the-art waterjet cutting machines available in-house and the capability to cut armoured plate and composite materials, we are able to work in niche markets such as Aviation, Space and Defence.

We are accredited to the latest ISO9001:2015 Quality standard and also operate in a range of other including automotive, formula 1, construction, engineering, marine, and oil & gas.

Materials we can cut up to 300mm thick:

Aluminium, Copper, Brass, Bronze, Carbon Steel, Stainless Steel, Iron, Acrylics, Plastics, Carpet, Cork, Foamex, Rubber, Glass, Fibreglass, Carbon Fibre, Wood, Leather, Silicone, Granite, Limestone, Marble, Slate, Ceramics, Composites and many more.Cutting Edge Quality

Depending on what the waterjet cut pieces will be used for, they may require different edge qualities which range from Q1 to Q5. Q1 is the fastest cut and is used for material separation, and slower cutting speeds from Q2 to Q5 are selected depending on edge finish requirements - parts requiring close tolerance geometry will require smoother edge finishes.Cut speed/edge quality is also often referred to as 100%, 80%, 60%, 40% and 20%.

Waterjet Cutting Benefits:

No Heat Affected Zone (HAZ)As opposed to flame, plasma & laser cutting, waterjet and abrasivejet cutting produce no heat affected zone to work harden the cut edges. This means that we are able to cut various metals, plastics and other materials without melting, distorting or warping them.

Incredible Precision

Waterjet/Abrasivejet Cutting gives us a way to routinely cut precision parts with tolerances as close as +/- 0.005" and better when required. Cutting is controlled by a computer and special software which follows profiles/part geometry designed using Computer Aided Design (CAD) software.